The pulp and paper industry is one of the most technically demanding sectors. Manufacturing paper requires a variety of specialized and highly-engineered machines. Pumping technology used in this industry must be precisely selected and set up for different types of fibers and products.

SEEPEX pumps meet these demanding requirements. That is why many leading pulp and paper producers rely on our pumps throughout their entire manufacturing process, e.g.:

- Raw stock preparation and treatment

- Paper finishing

- Coater concentration plants

- Stock center

- Bleaching unit

- Wastewater treatment plant

- Supply industry

The modular SEEPEX system offers technically and economically optimized solutions for virtually every application in the paper industry. Standard, 6L and tricam geometry with short and long pitches guarantee optimal adjustment. Optimized geometries with maximum metering accuracy are available for low pulsation operation. Mechanical seals are a proven technology to fulfill legal environmental regulations, technical requirements and economic considerations.

SEEPEX in the pulp and paper industry – epitomizes technically advanced and custom-manufactured pump solutions

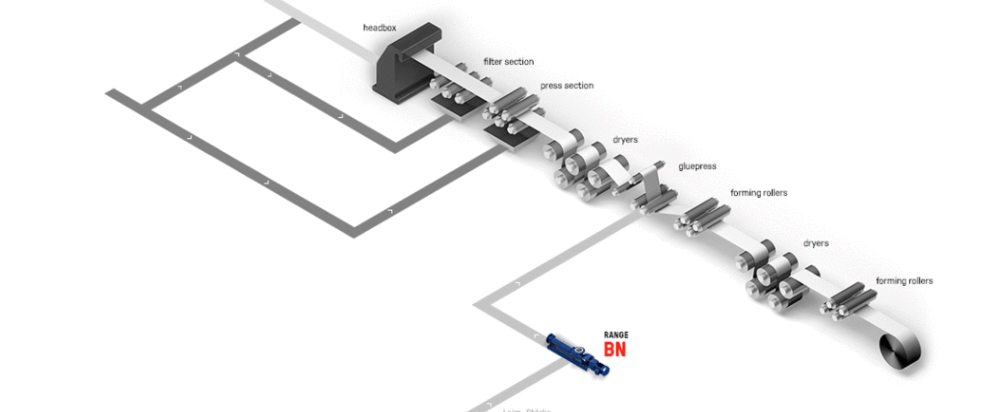

1. PAPER MACHINE

Paper machines are up to 200 meters long and produce up to 2,000 meters of paper per minute. The requirements for these massive machines are just as impressive. Transporting, metering and flushing starch and glue solutions to the paper web are particularly important processes.

SOLUTION:

SEEPEX pumps are ideally suited for coating paper webs after the drying section, to give them the required surface strength.

Sample application:

- BN and MD range pumps convey and meter glue and starch into the size press.

The SEEPEX pump solutions show their advantages through:

- Easy pumping of viscous media

- Gentle, low pulsation handling with accurate metering

Producing endless paper is a technically difficult and complex task – SEEPEX pumps master every requirement with poise.

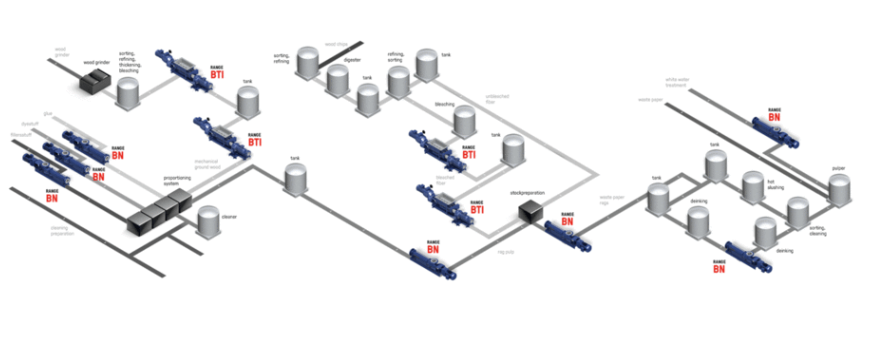

2. STOCK PREPARATION

In stock preparation, the fibrous materials of waste paper, wood and pulp are mechanically and chemically processed. Depending on the type of fibers used, paper is broken down into three groups: the wood-free or pulp-based group, the woody or wood pulp-based group and the waste paper-based group.

Besides fibrous materials, paper consists of water and auxiliary substances, both natural (kaolin, resin) or synthetic in origin (colorings)

SOLUTION:

SEEPEX pumps convey the respective fibers and meter the auxiliary substances in all areas of raw stock preparation.

Some sample applications:

- BN range pumps convey dye, filler material and glue to the stock center.

- BN range pumps convey waste paper pulp to the stock preparation area.

- BTI range pumps convey wood pulp or cellulose to the stock center.

SEEPEX pumps show their advantages clearly in stock preparation:

- Precise metering of auxiliary materials

- Gentle, low pulsation pumping

- Adjustable speed and conveying capacity

- Handles fluids at high temperatures

Conclusion: SEEPEX pumps are the ideal choice for all complex processes in stock preparation.

3. SUPPLY INDUSTRY

Filler and auxiliary agents are essential additives for the pulp and paper industry used to homogenize paper and guarantee its opacity and whiteness.

SOLUTION:

SEEPEX pumps are used in the production of filler and auxiliary agents and to fill and empty transport and storage containers. The pumps serve many leading suppliers reliably.

Some sample applications of SEEPEX pumps in the supply industry:

- For stock preparation: Bleaches and additives

- For the paper machine: Glue, starch, retention agents and others

- For the coating kitchen: Pigments, binding agents and additives

SEEPEX pumps convey low to highly viscous products with and without solids and low to high temperature products gently and with low pulsation and shear. Additionally, they impress with their high metering ability and their trouble-free transport of media such as coating colors, starch or auxiliary agents.

SEEPEX pumps make valuable contributions to the supply industry with these advantages.

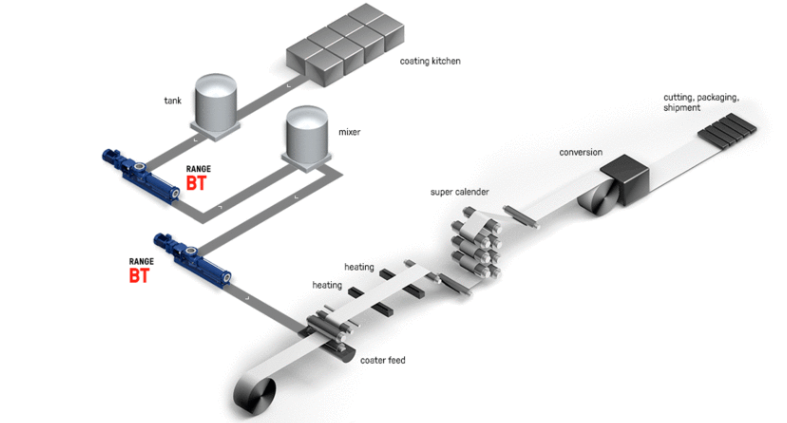

4. COATING KITCHEN

Paper is given an additional coating in the coating kitchen, where a special gloss, structure or specific effect is added. These finishing processes fulfill the various requirements of the processing industry and its consumers.

SOLUTION:

Coating kitchens are the main area of application for SEEPEX pumps which are particularly suitable for this task thanks to their flexibility.

Sample applications:

- BN range pumps convey coater from the vat to the mixer.

- BN range pumps feed the coating agent into the coating system.

High quality coaters contain pigments, binding agents and auxiliary agents such as brighteners and defoamers. SEEPEX pumps are used successfully for all of these types of fluids.

SEEPEX pumps provide special treatment for high-quality media:

- Low shear for gentle product handling

- Adjustable speed for precise flow rates

Conclusion: SEEPEX pumps contribute efficiently to finishing paper and cardboard in coating plants.

English

English