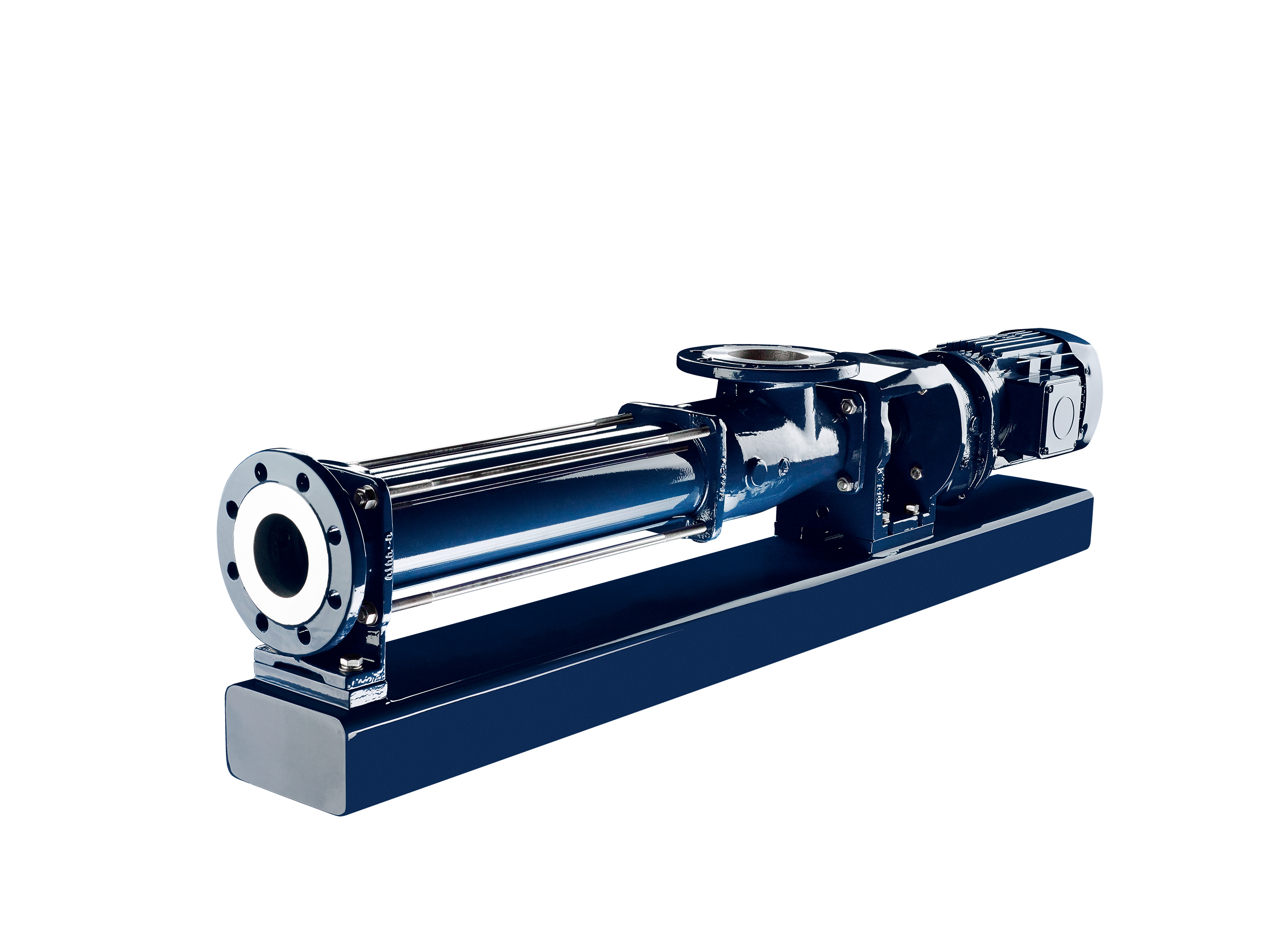

Bơm trục vít SEEPEX - BNA SERIESMã sản phẩm: BNA SERIES

|

|

N STANDARD PUMP

THE BASIS: Product group N pumps are the basis for SEEPEX progressive cavity pumps. They are used in almost all industrial sectors and convey low to highly viscous media with or without solids. Those benefits along with others ensure the pump’s economical operation.

KEY FACTS: Conveying capacit: 30 L/H - 500 M³/H0.132 - 2,200 US Gpmpressure: up to 96 BAR1,400

PSIPROPERTIES & BENEFITS:

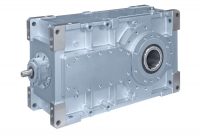

RANGE: The BN range pumps have a modern, compact, low-cost and user friendly design. SEEPEX progressive cavity pumps from the BNA range are designed to fulfill the exacting requirements of the Oil & Gas Industry and meet American Petroleum Institute (API) standards. BNA range pumps have rugged, heavy-duty castings in accordance with API 676 3rd Edition and casing parts made of super duplex stainless steel. The maximum containment pressure for both suction and discharge is 50 bar. The flanges are according to ASME B16.5 – suitable for two times the external forces and moments required by API 676. Additionally, SEEPEX offers fully API 682 compliant mechanical seals with optimized seal plans. ASTM materials, full traceability and compliance with NACE MR0175 are standard features. The pump can also be designed for gas hazardous areas.

Conveying medias:

Properties:

Benefits:

|

English

English